POSTDOCTORAL RESEARCH PROGRAM

DOROTHY is a postdoctoral research programme open to researchers from all disciplines who wish to focus on research into public health crises.

START

This interdisciplinary fellowship programme has been created in July 2021 by three leading Irish national agencies, and co-funded by the European Union's Horizon 2020 programme through Marie Skłodowska-Curie Actions.

OUTGOING

Fellowships will have an international outgoing phase of 18 months, followed by a return phase to Ireland of 18 months.

Research team

Applicant

Dr. Gurbir Kaur

Assitant Professor

Department of Civil Engineering

Thapar Institute of Eng and Tech, India

Outgoing phase supervisor

Dr. José Ignacio Álvarez Galindo

Full Professor Inorganic Chemistry

Head MATCH Research Group

Department of Chemistry

University of Navarra, Spain

Return phase supervisor

Dr. Sara Pavia

Associate Professor

Civil, Structural and Environmental Engineering Dept.

Trinity College Dublin, Ireland

Status of research

Progress made and results to date in relation to the key research objectives planned

To achieve the first research objective of the project, network mud, which is an industrial by-product generated during the refining of bauxite ore to form alumina using the Bayer process, was procured from the Alcoa industry, Lugo, Spain. network mud was oven-dried at 105°C to remove moisture before being used in further investigations. The chemical composition and mineral phase identification of network mud was obtained using X fluorescence (XRF) and X diffraction ( X), respectively. The phase transformation of compounds in network mud was studied by combined thermogravimetric analysis and differential scanning calorimetry (TGA-DSC). Based on the characterisation results, network mud owing to its favourable chemical composition (i.e., presence of iron oxide, silicon oxide, calcium oxide and alumina) has been established as a binder for cementitious materials. It was observed by means of laser diffraction measurements that network mud consists of fine particles; this characteristic is also beneficial for cementitious materials, and may lead to pore refinement in the cementitious matrices. Further, it was clear from the characterisation details that hematite (α-Fe2O3) and goethite (α-FeOOH) are the compounds or iron oxide phases which are found in abundance in network mud. Interestingly, hematite is a nontoxic and stable compound, which possesses a visible light active band gap and can be a potential catalyst for photocatalytic activity. In light of this observation, network mud has been thermally activated at 300°C and 600°C to transform its mineral phases, with the goal of increasing the concentration of hematite α-Fe2O3.

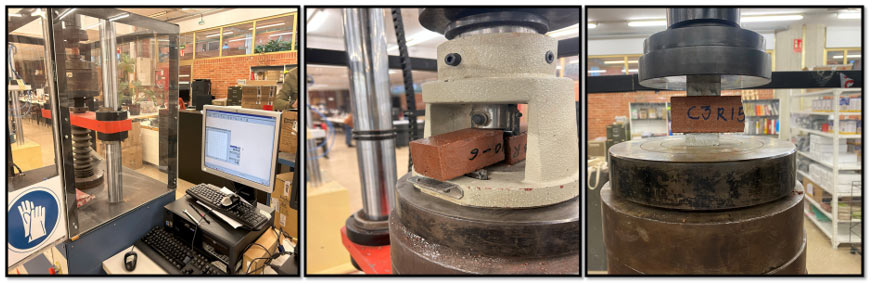

Cement (CEM III/A 42,5 N/SRC) procured under the industrial name 'Rezola FORTE' and siliceous standard sand conforming to EN 196-1 have been used in the present investigation to prepare mortars. The standard 1:3 cement-sand mortar prepared at 0.5 water-binder ratio has been designated as control mix. The cementitious mortars containing network mud (oven dried at 105°C and incinerated at 300°C and 600°C) as partial cement replacement (0-15% by weight of cement) were prepared and investigated for its mechanical strength (compressive strength and flexural strength). Prism specimens (40*40*160 mm) were cast to determine the compressive strength and flexural strength of mortars at 7 day and 28 days of curing. The universal testing machine of 5 tonnes capacity, manufactured by the Shimadzu corporation, was used to test the specimens for compressive strength and flexural strength. The porosity and pore size distribution of the mortars as obtained by mercury intrusion porosimetry technique has also been studied due to its significant impact on the material's properties, performance, and durability. The detailed insights into the microstructure and morphology of mortars were obtained by scanning electron microscopy (SEM). The findings of this objective indicate that incorporating network mud as a partial cement replacement up to 10-15% by weight appears feasible without significantly compromising the mechanical properties of cement mortars. This can help reduce cement consumption to some extent and provide a sustainable use for network mud.

Information updated on 3rd November 2024

More information soon

More information soon

Highlights on material characterizations

The universal testing machine of 5 tonnes capacity, manufactured by the Shimadzu corporation, was used to test the prism specimens (40*40*160 mm).

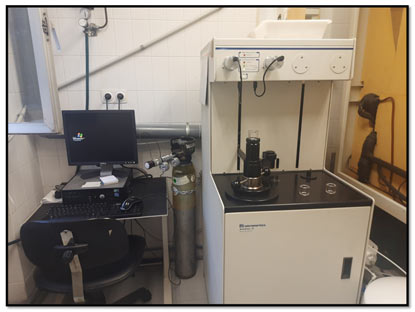

The instrument used for thermogravimetric analysis was the SDT650 from TA Instruments, New Castle, DE, USA, and data evaluation was performed using TRIOS, also from TA Instruments.

Porosity measurements were made by mercury intrusion porosimetry (MIP) technique with AutoPore IV 9500 V1.07 mercury porosimeter (Micromeritics instrument corporation).

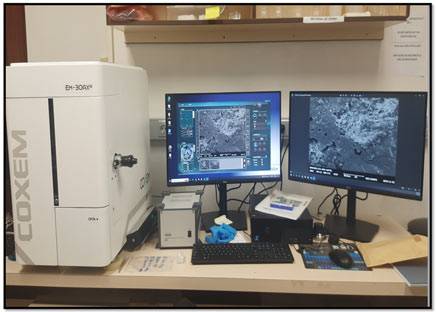

The microstructure of mortars studied by the scanning electron microscopy (SEM) manufactured by the COXEM EM-30N (COXEM Co., Ltd., Daejeon, Republic of Korea) coupled with a Quantax Compact 30 Bruker EDS (Bruker Nano GmbH, Berlin, Germany).

X diffraction (XRD) measurements were conducted using a Bruker D8 Advance diffractometer. The data analysis was performed using DIFFRACplusEVA® software from Bruker.

The chemical composition of materials was determined using the Bruker S2 Puma apparatus, equipped with an X tube containing a silver anode.

Dissemination activities

- Tena-Santafé VM, Kaur G, Fernández JM, Navarro-Blasco I, Alvarez JI. Hydrophobic and Oleophobic Photocatalytic Coatings for Building Substrates: A Bibliometric Perspective (2010-2025).. Coatings 2025; 15(12): 1391, 1-39 <DADUN>

- G. Kaur, J.M. Fernández, I. Navarro-Blasco, S. Pavía and J.I. Alvarez

Visible Light Active Fe2O3/TiO2 Heterostructure over Cementitious Material for NOx Abatement

4th International Conference on Responsible Consumption and Production (INCORCP 2025). Chania, Crete, Greece, 23-24/09/2025. >DADUN

- G. Kaur, J.M. Fernández, I. Navarro-Blasco, S. Pavía and J.I. Alvarez

network Mud Mortars: A Sustainable Solution for the Restoration of Contemporary Buildings

7th Historic Mortars Conference (HMC 2025). Padova, Italy, 02-04/09/2025. >DADUN

Book chapter:

- G. Kaur, J.M. Fernández, I. Navarro-Blasco, S. Pavía and J.I. Alvarez

network Mud Mortars: A Sustainable Solution for the Restoration of Contemporary Buildings

Jacopo Bonetto, Simone Dilaria, Caterina Previato (Eds.) "7th Historic Mortars Conference (HMC 2025), Padova". Colection COSTRUIRE NEL MONDO ANTICO, 11; Edizioni Quasar, Rome, 2025, pp. 569-572. ISBN 978-88-5491-636-4. DADUN

- G. Kaur, J.M. Fernández, I. Navarro-Blasco, S. Pavia and J.I. Alvarez

From Toxic Waste to Sustainable Building: network Mud Cementitious Composites for Environmental Remediation.

4th International Conference of Sustainable Building Materials (ICSBM 2025). Eindhoven, the Netherlands, 10-13/08/2025. > DADUN

- G. Kaur, J.M. Fernández, I. Navarro-Blasco, S. Pavía and J.I. Alvarez

Evaluation of cement mortars incorporating calcined network mud: Characterisation and strength development.

3rd International Conference on Construction, Energy, Environment and Sustainability (CEES2025), Bari, Italy, 11-13/06/2025 >DADUN

- G. Kaur, J.M. Fernández, I. Navarro-Blasco, J.I. Alvarez and S. Pavía

Potential use of network mud in cementitious materials for environmental remediation

3rd International Conference on Green Construction (ICGC2024)

Córdoba, Spain, 21-23/10/2024. Oral Presentation. >DADUN

- G. Kaur, J.M. Fernández, I. Navarro-Blasco, S. Pavía and J.I. Alvarez

Transforming waste network mud into sustainable cementitious materials for self-cleaning applications

congress of Sustainability and Applied Circular Economics (CSECA2024)

Madrid, Spain, 11-12/12/2024. Oral Presentation. >DADUN

→ Prof. Kaur's work on "Developing sustainable construction materials with antimicrobial properties to combat airborne infections in indoor environments" has gained attention in the Dorothy's Blog. At the same time, progress on her research and current achievements are reflected in the DOROTHY MSCA COFUND Annual Bulletin-2025.

→ Prof. Kaur has attended the 4th International Conference on Responsible Consumption and Production (INCORCP 2025) which took place in Chania, Crete, Greece, on 23-24 September 2025, organized by EURECA-PRO (the European University on Responsible Consumption and Production).

→ Prof. Kaur has attended the 7th Historic Mortars Conference (HMC 2025) held in Padova, Italy, on 2-4 September. Her contribution is available at the University of Navarra's repository: >DADUN

→ Prof. Kaur has attended 4th International Conference on Sustainable Building Materials (ICSBM 2025) held in Eindhoven, The Netherlands, on 10-13 August. Her talk is available at the University of Navarra's repository: >DADUN

→ Prof. Kaur has attended the CEES 2025 Conference on Construction, Energy, Environment & Sustainability which took place in Bari, Italy, on 11-13 June. Her talk dealt with "Evaluation of Cement Mortars Incorporating Calcined network Mud: Characterisation and Photocatalytic activity". >DADUN

→ Prof. Gurbir Kaur has delivered the lecture "From Toxic Waste to Sustainable Building" at the scientific event "Time to share: Circular Economy", organized by the University of Navarra on 26th May 2025.

- University of Navarra

- Diario de Navarra

→ Dr. Gurbir Kaur attended DOROTHY COFUND's 2nd training event on 'Public health crises -national and global perspective' organised by Irish Research Council supported by EU Commission Marie Skłodowska-Curie Actions, Health Research Board and Environmental Protection Agency on 10th and 11th December 2024 in Dublin, Ireland.