These are some of the equipment available at department for the different groups of research (Thermal and Fluids, Machines and Vehicles, Robotics and Control, design Industrial or Mechanics of Materials and Advanced Manufacturing) to develop their purposes.

MACHINING CENTERS

- 5-axis machining center UMC-500SS: 12000 rpm spindle with ISO 40 taper and 22.4 kW power.

-3-axis machining center VF-3SS with rotary table HRT210 (4th axis): 12000 rpm spindle with ISO 40 taper and 22.4 kW power.

-VF-2SS machining center: 12000 rpm spindle with ISO 40 taper and 22.4 kW power.

-DT-1 machining center: 10000 rpm spindle with ISO 30 taper and 11.2 kW power.

-Super Mini Mill 2 machining center: 10000 rpm spindle with ISO 40 taper and 11.2 kW power.

CNC LATHES

- ST-20 CNC lathe with APL automatic parts loader: 4000 rpm spindle and 14.9 kW power.

-ST-15 CNC lathe: 4000 rpm spindle and 14.9 kW power.

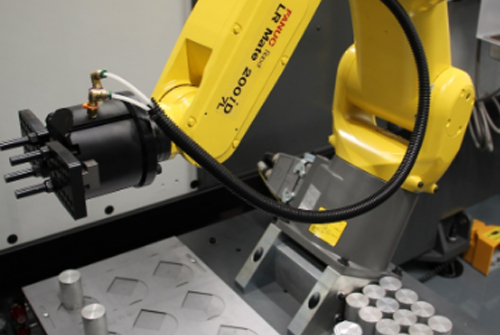

-ST-10Y+PKG LR Mate 200iD Y-axis turning center: spindle speed 6000 rpm and power 11.2 kW.

-TL-2 CNC lathe: spindle at 1800 rpm and power 7.5 kW.

-Renishaw 500 S Flex: PBF-L technology with one laser / Build volume: 250 x x mm / Wide range of supported metal powders.

-Stratasys Objet60 Connex 3: Based on PolyJet photopolymer-jetting technology / Featuring 16-micron super-thin layers / Multi material printing capabilities / Volume: 256 x x mm.

-Stratasys F170: Based on FDM technology with 254-micron layers / Materials: ABS, ASA, PLA and elastomers / Volume: 254 x x x mm.

-Raise3D Pro3 Plus HS: Based on FDM technology with Dual Extruder Print. Volume: 255 × 300 × 605 mm.

-Flying Tumaker: Nine extrusion printers. Bowden type / One extrusion printer. Direct drive /One pellet printer / Build volume: 200 x x mm and 295 x x mm.

-Creality Ender 3 S1: Sixteen extrusion printers. Bowden type / Direct extruder with filament sensor / Build volume: 220 x x mm.

-Formlabs Form3: SLA technology / Quick release system / Build volume: 145 × 145 × 193 mm.

-Elegoo Saturn 3: DLP technology / Build volume: 220 x x mm.

- 1 Franka Emika collaborative robot with 7 axes.

- 1 Fanuc LR Mate 200iB 6-axis industrial robot.

- 1 industrial robot Denso VP-6242G2M-UL of 6 axes.

- 1 industrial robot Mitsubishi PA-10 of 7 axes.

- 1 Cartesian robot classroom Biele with 3 axes.

- 1 Phantom Premium 1.5 haptic interface with 6 active GDL.

- 1 Phantom Premium 1.0 haptic interface of 3 active GDL.

- 3 Phantom Omni haptic interfaces of 3 active GDL.

- 1 Stäubli TX60 robot.

- 1 adaptive robot gripper Robotiq 2-finger 85.

- 8 benches with Beckhoff EtherCAT PLC, digital I/O, analog output.

- HandySCAN 300 scanner from Creaform 3D: Laser technology capable of 200000 samples/sec. / Resolution 0.1mm and precision up to 0.04mm.

-Miraco PRO: Structured light technology / Up to 0.02mm precision, 0.05mm accuracy.

- SENSE 3D scanner from 3DSystems: Structured light technology / Spatial resolution of 0.9mm at 0.5m.

- Vaquform DT2: Sheet Size: 330 mm x mm. / Forming Area: 280 MM x mm. / Heater Temperature: up to 280 °C.

-Mayku multiplier: Forming Area: 380mm × 380mm (250 x mm with the reducing plate) / Maximum chamber pressure: 60 psi / Heater Temperature: up to 225 °C.

-MCP KSA 100: Max. injection pressure: 410 cafeteria. / Max. injected material: 100 grams.

-MCP 4/01: Vacuum level: 0.5 mbar / Casting capacity: 1 l / Max. size for the mold: 450 x x mm.

-Ovens for storage and curing: VGO 115S, VGO 200S.

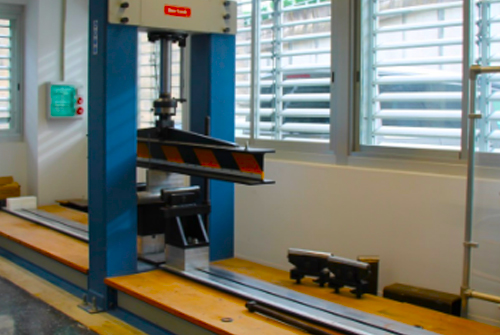

- Ibertest PEV200-W: Flexure testing machine / Up to 200 kN force and 6 meters specimen length.

-Ibertest MEHP2000 5W: Testing machine for compression of concrete specimens / Up to 2000 kN force.

- Bridge crane up to 1 ton.

- LEICA TCRM 1205: Total station for topography measurements / Motorized. Long range / Angle and distance measurement with and without reflector.

- Proceq Profometer 5: Reinforcing bar detector for reinforced concrete / Determination of concrete cover / Determination of bar diameter / Location and orientation of bars.

-Haver&Boecker EML 200 Pure: Aggregate screening machine / Screens available from 40 mm to 63 microns.

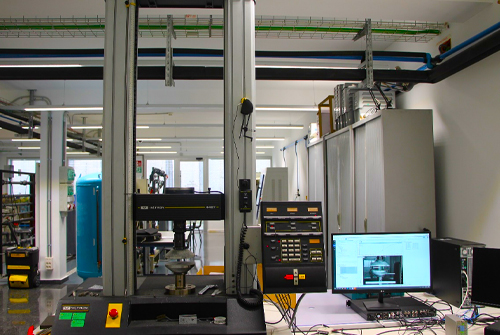

- Instron 4467: Universal testing machine / Up to 30 kN. Maximum stroke 1100 mm. / Software for test recording.

-Instron 44mini: Universal testing machine / Up to 500 N. / Maximum stroke 350 mm. Maximum stroke of 350 mm. 7 Software for recording tests.

-Instron GL50 Trav 50: Uniaxial extensometer for strain measurement. / Travel: 50 mm / Initial distance: 50 mm.

- Wolpert 7004 H1102: Charpy testing machine / Material toughness measurement / Capacity: 4 Joules.

-Glass desiccator: Silica salt desiccator / Capacity: 10 liters.

- EPILOG HELIX24: CO2 laser with 40 W. / Build chamber: 610 mm x mm. / Max. resolution: 1200 dpi.

-Prototyping lab: it has 15 workbenches of 2000 x mm and 7 tool carts for developing prototypes.

- Coordinate measuring machine TIGO SF 565: Measuring range: X mm/Y=580 mm/Z=500 mm. /

-DEA Mistral 07.07.05 coordinate measuring machine: Measuring range: X mm/Y=710 mm/Z=460 mm.

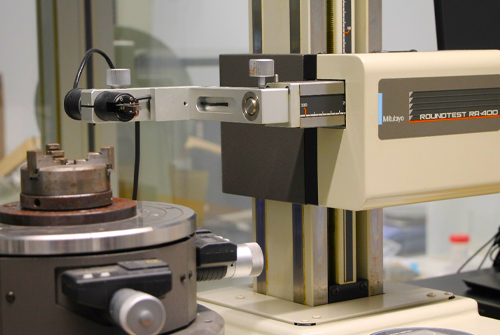

-Roundtest RA-400 from Mitutoyo: Roundness measuring machine.

-Mitutoyo Surftest SJ-301: Portable roughness tester.

- Taylor Hobson's Form Talysurf Plus: Stylus profilometer with 50 mm travel for surface texture measurement and analysis.

-Leica Mz 125 stereo microscope: 12.5:1 magnification changer, 0.8×-10×. / 10 positions attachable at 1, 1.25, 1.6, 2, 2.5, 3.2, 4, 5, 6.4, 8.

-SmartWLI-basic microscope (gbs): 3D surface measurement without contact. / Measuring principle: White light interferometry / Field of view [m]: 2264x1723 / Height measuring range [µm]: Up to 400.

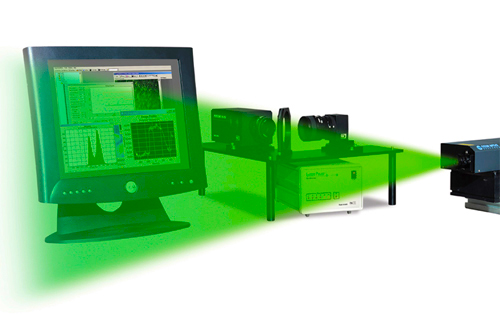

- TSI laser flow measurement system: Stereoscopic Particle Image Velocimetry (PIV) / Laser Induced Fluorescence (LIF) / Global Size Velocimetry (GSV). / Global Size Velocimetry (GSV).

-Hot Wire Anemometers: Hot-wire anemometry system: CTA Streamline model with two channels, an automatic calibrator and with a 3D traverse system from Dantec Dynamics.

- NVGATE OROS 35: Real-time noise and vibration multi-analyzer / 8 BNC dynamic inputs / 2 BNC outputs + 2 tachometers / Up to 102 kS/s / AC/DC/ICP/TEDS / Filters, integrator, shunt / NVGate software. / Filters, integrator, shunt / NVGate software.

-GOM Aramis Adjustable 12 MP: 3D DIC equipment. Digital Image Correlation / Displacement and deformation measurement / 8 analog inputs / Virtual extensometer for universal testing / Issue from work: Up to 770x590x590 mm.

- Strain gage equipment: 1-channel dynamic amplifiers / 4-channel static amplifiers / Strain gage equipment for metals and concrete.

-High speed cameras: PHOTRON FASTCAM MiniAX 200. Up to 900 Kfps; 6400 fps full frame (1024x1024). / MotionXtra HG 100-K/LE. Up to 100 Kfps.

-Thermal Iaging Camera: ThermaCam P25 with the research package from Flir Systems.