Industrial design

The group of research interdisciplinary at design Industrial collaborates with industry, universities, technology and medical centers on research projects that advance the state of the art in various fields:

![]() Design for Additive Manufacturing with functional materials including topological optimization of the geometry, printing process parameters to optimize the final functionality of the material itself, etc.

Design for Additive Manufacturing with functional materials including topological optimization of the geometry, printing process parameters to optimize the final functionality of the material itself, etc.

![]() Development of new intelligent methodologies focused on solving problems related to the industrial design centered on Username.

Development of new intelligent methodologies focused on solving problems related to the industrial design centered on Username.

![]() Design and development of Biomedical Devices

Design and development of Biomedical Devices

![]() Methodologies to incorporate AI in industrial design processes for Academia and Industry.

Methodologies to incorporate AI in industrial design processes for Academia and Industry.

The group of design Industrial is actively collaborating with the laboratory Biomedical Engineering of the School of Medicine of the University of Navarra.

The partnership in these topics can be carried out either in the scope of research projects of public calls at regional, national or European level, or through bilateral collaborations with the partner institution. Depending on the project, the temporary framework and the funding available, this partnership can benefit from the attendance of the students of Degree/Master's Degree or of students of doctorate of the University of Navarra.

Members of the group

Members of the group

María de la Paz Morer Camo

Chair

(Coordinator)

+34 943 219877 Extension: 842410

View CV "View CV of María de la Paz Morer Camo".Aitor Cazón Martín

Associate Professor

+34 943 219877 Extension: 842378

View CV "View Aitor Cazón Martín's CV".María Isabel Rodríguez Ferradas

Professor Contratada Doctora

+34 943 219877 Extension: 842497

View CV "View CV of María Isabel Rodríguez Ferradas". Facilities and equipment

Facilities and equipment

DIGITIZING DEVICES AND SOFTWARE FOR REVERSE ENGINEERING

► HANDYSCAN 300 SCANNER FROM CREAFORM3D: Laser technology capable of 200000 samples per second, Resolution of 0.1 mm and precision up to 0.04 mm.

► MIRACO PRO: Structured light technology, Up to 0.02 mm precision, 0.05 mm accuracy.

►SENSE 3D SCANNER FROM 3DSYSTEMS: Structured light technology, Spatial resolution of 0.9 mm at 0.5 m.

►SOFTWARE FOR REVERSE ENGINEERING: CREO REX Module, Magics.

ADDITIVE

MANUFACTURING I

► RENISHAW 500 S FLEX: PBF-L technology with one laser, Build volume: 250 x x mm, Wide range of supported metal powders.

►STRATASYS OBJET60 CONNEX 3: Based on PolyJet photopolymer-jetting technology, Featuring 16-micron super-thin layers, Multi material printing capabilities, Volume: 256 x x mm.

►STRATASYS F170: Based on FDM technology with 254-micron layers, Materials: ABS, ASA, PLA and elastomers, Volume: 254 x x x mm.

► RAISE 3D PRO3 PLUS HS: Based on FDM technology with Dual Extruder Print, Volume: 255 × 300 × 605 mm.

ADDITIVE

MANUFACTURING II

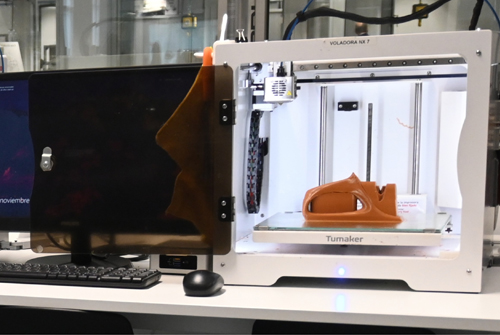

► TUMAKER VOLADORA: Nine extrusion printers. Bowden type, One extrusion printer. Direct drive, One pellet printer, Build volume: 200 x x mm and 295 x x mm.

► CREALITY ENDER 3 S1: Sixteen extrusion printers. Bowden type, Direct extruder with filament sensor, Build volume: 220 x x mm.

► FORMLABS FORM3: SLA technology, Quick release system, Build volume: 145 × 145 × 193 mm.

ELGOO SATURN 3: DLP technology, Build volume: 220 x x mm.