In the picture

Wind turbine propellers [Pixabay].

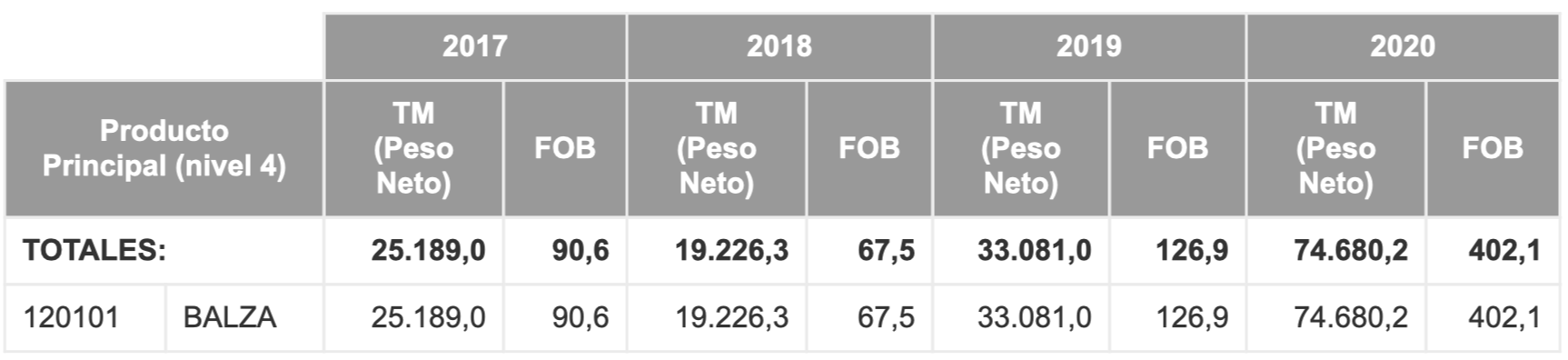

The global commitment to renewable energy sources has increased wind power generation; in turn, the construction of new 'windmills' has boosted the consumption of balsa wood: a wood that is as light as it is resistant, ideal for wind turbine propellers, especially for smaller ones. Ecuador is the main exporter - in 2019 it doubled its international sales and in 2020 it doubled them again - and China is the biggest buyer. The business has fuelled illegal exploitation of this tropical tree and raised concerns about its sustainability management .

The balsa is a tree native to South America that grows especially in the tropics as it needs a humid climate and fertile soil to develop properly. Each tree can grow to a height of 25 to 30 metres, which is very beneficial for its growers as it offers a high performing per tree. In addition, the perfect age for cutting the tree is only three to four years after planting, which allows high profits to be obtained in a short time.

Its characteristics as a light and soft, yet highly resistant wood - strong and light at the same time - make it perfect for the manufacture of cladding for cruisers, skis, bridges... and especially for wind turbine propellers. Turbine blades are partly made from balsa wood because it is cheaper than metal, more resistant than plastic and, unlike these materials, it is ideal for adapting and recovering on windy days. As industry expert Carlos Martinez-Thiem specifies, balsa tends to be used to a greater extent in small turbines. "Conventional wind turbines have blades that are generally made from fibreglass, in a proportion that can be around 24 tonnes GRP, with just over a tonne of wood, and average tonne of metal," he says. This means that when conventional wind turbines, which have a lifespan of 10 to 20 years, are discarded, it is not worth recycling the wood, as it would be laborious and costly.

With the worldwide commitment to wind energy and the growing demand for windmills, the international demand for balsawood has also increased. However, as Martínez-Thiem explains, the oscillation of its price, with its recent increases, is not so much due to the global evolution of this demand as to other factors, such as the vicissitudes in the possibilities of access to the material or in global transport.

Since South America has the perfect tropical climate for the cultivation and harvesting of balsawood, it is logical that the largest producer and exporter of balsawood is a country in this region. The first place goes to Ecuador, which markets 20.3% of balsawood available globally. Other South American exporting countries are Chile (3.92%) and Brazil (3.77%), so that the three of them account for almost a third of the world market.