Innovating in sustainable magnets to boost Europe's energy autonomy

18 | 11 | 2024

The project seeks to pave the way towards a more autonomous and greener Europe in the context of energy and sustainable mobility .

The technology center Ceit will play a key role in producing large batches of metal powders of novel alloys required for the manufacture of the new magnets and researching critical aspects of the gas atomization process through numerical simulation and experimentation.

The transition to cleaner energy and a green mobility is essential for Europe to achieve its carbon neutrality targets, as set out in the European Green Pact. However, this progress depends on critical raw materials, in particular rare earths, which are essential for manufacturing permanent magnets. Currently, more than 90% of these materials come from China, which creates a vulnerability for the development of strategic European sectors, such as renewable energies or the electric vehicle industry.

To address this challenge, Ceit is participating in MagNEO, a €7.7 million European project that will develop a new generation of sustainable rare-earth-free magnets. This initiative seeks to decrease dependence on materials such as neodymium and praseodymium, essential for energy or automotive applications, by promoting a more autonomous and sustainable European supply chain for magnet manufacturing.

A leap towards sustainable magnets in Europe

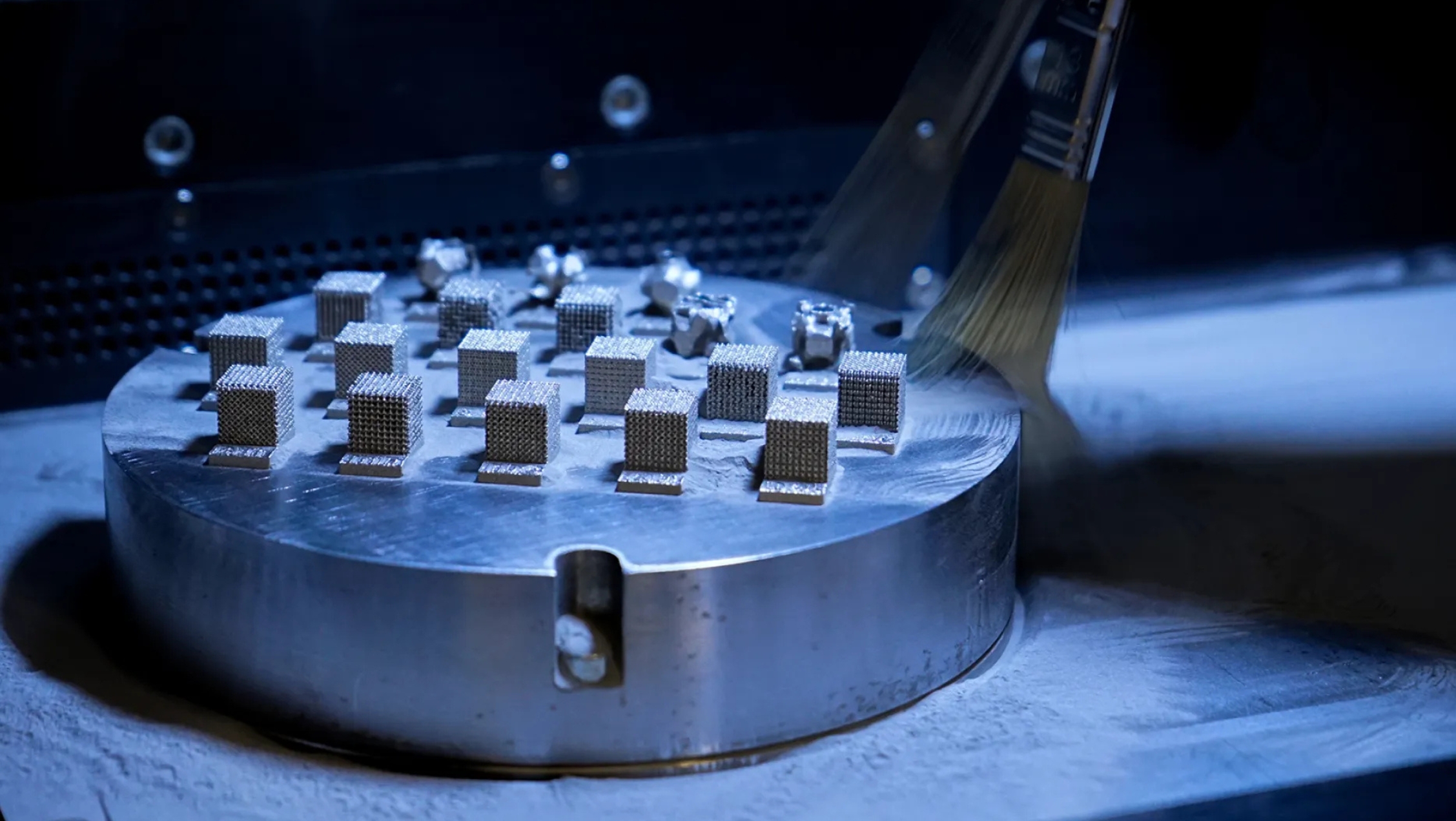

With this projected increase in demand for rare earths in sectors core topic, the ability to manufacture magnets free of these elements becomes a strategic priority. In this context, the project MagNEO will develop new AlNiCo (aluminum, nickel and cobalt) and high entropy alloys (HEA), both free of rare earths and with a high performing at elevated temperatures. These innovative magnets, manufactured using advanced additive manufacturing techniques, are intended for applications in wind turbines, high-speed motors and other systems.

Role of Ceit

Ceit will play a key role in project, using its previous experience with a gas atomization unit from laboratory and its knowledge in numerically simulating critical aspects of the gas atomization process using computational fluid dynamics (CFD) software to increase the performance of its new industrial-scale atomization unit that will produce large batches of the powders required for the manufacture of these new magnets. The gas atomization process allows obtaining metallic powders with optimal characteristics for the different additive manufacturing techniques. Ceit will be in charge of analyzing the influence of the different operational variables, as well as designing and testing new and more efficient components to ensure a scalable industrial manufacturing of the sustainable magnets developed within project MagNEO. In addition, it will continue with the task of computationally modeling the different stages of the process using multiphase models, in order to predict the particle size distributions of the resulting powders and to choose the optimal atomization conditions in advance.

A more sustainable and autonomous Europe

The project MagNEO, coordinated by the Norwegian institute of research SINTEF, includes sixteen partners from ten European countries, including technology organizations, technology providers, manufacturers and universities, partnership .

MagNEO thus represents a great opportunity to reduce Europe's dependence on critical materials, strengthening the resilience of the supply chain in strategic sectors.

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency (HADEA). Neither the European Union nor the granting authority can be held responsible for them.