Impulsamos el desarrollo de materiales avanzados para el transporte y almacenamiento de hidrógeno en el proyecto H2MAT+

We promote the development of advanced materials for hydrogen transport and storage at project H2MAT+

25 | 11 | 2024

Ceit will provide expertise in advanced materials and simulations to overcome the technical challenges posed by hydrogen as an energy vector

Hydrogen, known as the energy vector of the future, has characteristics that make working with it extremely complex: it is the lightest chemical element in existence, it has a B facility for combining with other elements and changing their properties, and its volumetric energy density is leave. These peculiarities create significant challenges, including the embrittlement of materials and their efficient storage.

To address these challenges, the project H2MAT+, funded through the Basque Government's ELKARTEK program, seeks to develop new metallic Structures capable of resisting the negative effects of hydrogen and improving storage efficiency.

Hydrogen embrittlement is a phenomenon where metallic materials become more susceptible to breakage when they are at contact with hydrogen. H2MAT+ addresses this challenge by development of high entropy alloys (HEA) and new types of steel specifically designed to resist hydrogen-rich environments. In addition, Structures steel-aluminum hybrids will be evaluated, allowing their behavior and strength under demanding conditions to be studied.

At framework of H2MAT+, Ceit leads the work package focused on the study of hydrogen interaction with materials. His expertise in materials simulation and characterization will be core topic to investigate how hydrogen is absorbed, adsorbed and desorbed, and how these interactions affect the mechanical properties of materials. The ultimate goal is to design materials that are less susceptible to embrittlement by optimizing their microstructure for hydrogen transport and storage applications.

To this end, Ceit will employ advanced simulation techniques, such as hydrogen diffusion modeling coupled to crack propagation using phase field methods. These simulations will allow predicting the behavior of materials in the presence of hydrogen, facilitating the development of safer and more efficient Structures .

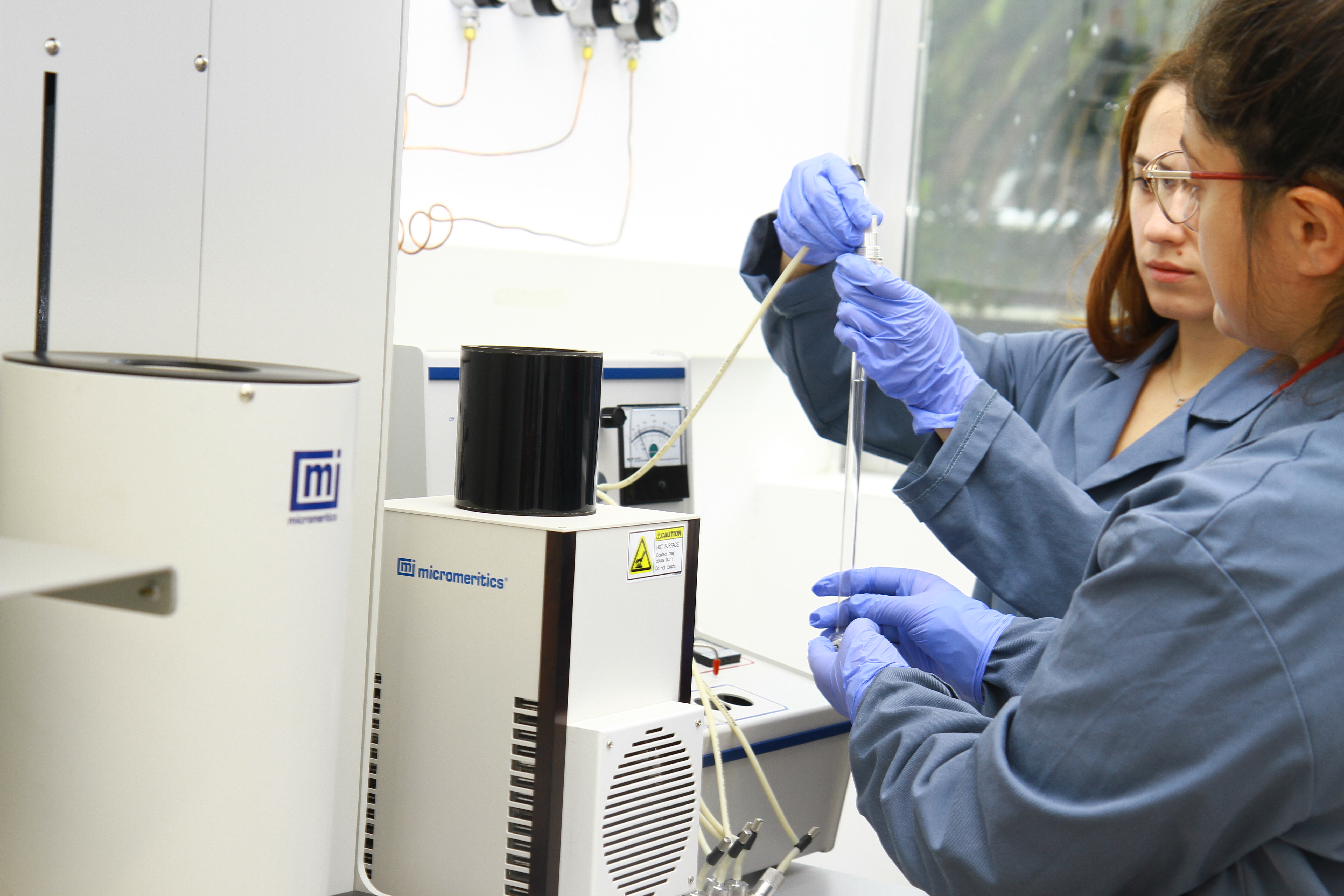

Ceit will also apply solid-state diffusion bonding technologies, such as the HIP (Hot Isostatic Pressing) process, a technique that has proven effective in the manufacture of robust components for demanding environments. In addition, the facilities and laboratories at Ceit will enable the production and assessment of prototypes in terms of both microstructural and mechanical properties before and after being subjected to hydrogen conditions.

The laboratory at Ceit, recently equipped thanks to a subsidy from the AZPITEK program of the Basque Government, allows the exhaustive characterization of materials at contact with hydrogen. These capabilities include tensile, toughness and fatigue mechanical tests to evaluate the strength of the alloys developed, as well as experiments to measure their hydrogen absorption capacity.

H2MAT+ is subsidized by the department of Industry, Energy Transition and Sustainability of the Basque Government and brings together a consortium formed by Azterlan, Tubacex Innovación, Tecnalia, UPV/EHU, Vicinay Marine Innovación, Clúster de Energía and Ceit, under the coordination of Mondragon Goi Eskola Politeknikoa (MGEP).

project subsidized by the department de Industria, Transición Energética y Sostenibilidad del Gobierno Vasco (Programa ELKARTEK 2024) Eusko Jaurlaritzaren Industria, Trantsizio Energetiko eta Jasangarritasun Saila (ELKARTEK 2024 Programa) diruz lagundutako proiektua Project funded by the Department of Industry, Energy Transition and Sustainability of the Basque Government (ELKARTEK 2024 Programme)