"My goal is to lead research lines on bone implants and tissue engineering."

Naiara Rodríguez is a professor at Tecnun, where she connects traditional engineering subjects with new applications from the biomedical world.

PhotoCommunication Service/NaiaraRodríguez

18 | 12 | 2020

Naiara Rodríguez is a professor at Tecnun-University of Navarra, and Research Fellow of IKERBASQUE, Basque Foundation for Science. Naiara holds a PhD in Bioengineering from Imperial College London and her research focuses on bone biomechanics, translating technological solutions to clinical applications. Related to her profile multidisciplinary , she has taught classes and led student projects that are at the interface between Engineering and Biomedicine. She completed the programs of study in Industrial Engineering at Tecnun, after developing the project end of degree program at Massachusetts Institute of Technology (2011) and was awarded with the scholarship pre-doctoral of the Basque Government to perform her doctorate at Imperial College London (2011-2015).

What was the focus of your doctoral thesis ?

In order to improve bone treatments, my thesis focused on characterizing mechanical and structural properties of pathological bones. I was teaching assistant for several subjects at Degree and Master's Degree in Bioengineering at Imperial College London, a pioneer in Europe in offering programs of study higher degrees in Bioengineering. My role was to identify areas of improvement in craniofacial surgery, developing projects that integrated biomedical engineering and clinical science. In 2017 I joined the School of Engineering at Mondragon Unibertsitatea and taught several subjects in the Degree Biomedical Engineering and the new Master's Degree in Biomedical Technologies. I was part of the group of research in Surface Technologies, where I focused on the field of biomaterials.

In 2017 she was awarded the Young Basque Investigator Award by Bizkaia Talent and SRUK/CERU in recognition of her international research career.

That's right, and after receiving the prestigious scholarship Ikerbasque Research Fellowship (2019-2024), my goal is to lead lines of research on bone implants and tissue engineering, and then transmit my knowledge to Tecnun students, thus connecting traditional engineering subjects with new applications in the biomedical world.

Why did you decide to join Tecnun?

Apart from the good memory I had of Tecnun from degree program, I was attracted by the fact that it is a Research University, i.e. that it promotes a degree program combining teaching with research. In the field of biomedical engineering, for my research to make sense, it is essential to collaborate with clinicians and biologists, and in this respect Tecnun has a privileged position as it has close ties with CUN and CIMA. On the other hand, in the field of professor, I was attracted to model educational and the balance sought in offering new areas of knowledge, but without leaving aside what would be more traditional engineering.

What is the line of research you are working on?

In general, my research has focused on bone mechanics. During the doctorate I examined the mechanical properties of bone along its hierarchical structure, focusing particularly on changes due to aging and skeletal pathology. Then, during post-doc at the hospital, I worked with surgeons characterizing the properties of the skull of infants born with craniofacial anomalies and generally bringing an engineering point of view to treatments and surgical techniques. Seeing the industry in the Basque Country and the European trends in topics of research, I applied for the Ikerbasque Research Fellowship (2019-2024) to continue researching in bone biomechanics topics, but focusing on the design optimized orthopedic implants and tissue engineering to design new bone substitutes. I officially started the fellowship in November 2019, so these are the topics I will be working on at Tecnun as part of the group from research of Structures and Fabrication.

Any specific project that you are working on and can give us more information about data?

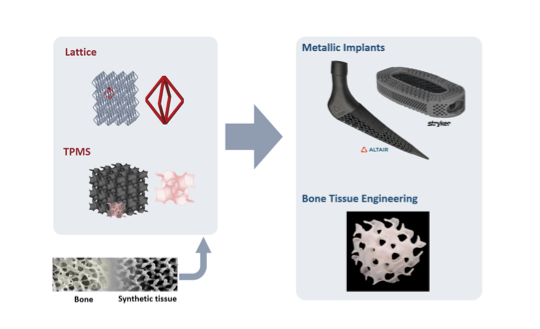

We are working on a project of porous Structures for biomedical applications: current trends in orthopedic biomechanics are based on mimicking the complex three-dimensional structure of trabecular bone so that there is a higher affinity between the implant and the surrounding bone. To this end, we are analyzing the design, the modeling and advanced fabrication of Structures lattice (rod-based) and TPMS (surface-based) cells subject . These Structures possess mechanical and geometrical qualities that make them very promising for orthopedic applications. Based on these Structures, we have several open projects.

Figure 1: Porous Structures based on bars (lattice) or surfaces (TPMS) that mimic bone structure can be used to develop orthopedic implants or for tissue engineering applications.

Por un lado, estamos trabajando en Implantes de cadera optimizados, en colaboración con el departamento de Cirugía Ortopédica y Traumatología de la CUN. Cada vez se ponen implantes a pacientes más jóvenes (<60años), y como la durabilidad de dichos implantes ronda los 15-20años, esto supondrá que muchos de estos pacientes necesitarán una cirugía de reemplazo en el futuro. Estas intervenciones son muy complicadas, ya que el hueso que rodeaba el implante se ve alterado con el tiempo. Es por ello por lo que estamos buscando nuevas soluciones que incrementen la durabilidad de los implantes, convirtiendo los implantes macizos en estructuras porosas que ayuden la integración y regeneración del tejido óseo. En el grupo de Estructuras y Fabricación trabajamos el diseño, la modelización computacional, la fabricación híbrida y la caracterización mecánica de estos implantes.

On the other hand, we are also working with scaffolds for bone tissue engineering, with the ultimate goal of replacing metal implants with bone substitutes, goal . Every year, millions of people around the world suffer from bone tissue defects due to various causes including trauma, tumor resections and aging. When bone defects are larger than a certain critical size, the bone is not able to regenerate, which motivates the need for Tissue Engineering of bone. Tissue engineering is based on three pillars: a biodegradable scaffold that provides transitional support until the tissue regenerates; cells that invade this scaffold; and signals that make these cells sense that they are in a physiological environment, and thus generate functional tissue. From the group of Structures and Fabrication and we want to develop biodegradable scaffolds based on porous Structures that are 3D printable and that respond to the mechanical needs of bone. For this, we have collaborations with the Basque Center of Transfusions and Human Tissues (CVTTH), BCMaterials, Mondragon Unibertsitatea and CICBiogune.

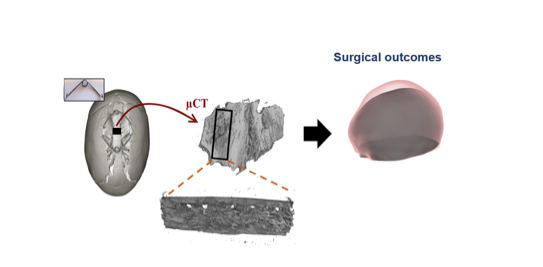

In turn, we are also collaborating with department of Plastic, Reconstructive and Aesthetic Surgery to develop new implants with report so that they can be operated from the outside. Finally, I continue to collaborate with the Great Ormond Street Hospital for Children (London) to improve treatments for patients with craniofacial diseases. In particular, I advise them on cranial bone characterization.

Figure 2: Analyzing the cranial bone structure of infants with craniofacial disease financial aid to predict surgical outcomes.