Finaliza FABRICARE, el proyecto de industria inteligente liderado por Ceit que impulsa una nueva generación de fábricas colaborativas, seguras y eficientes

FABRICARE, the smart project led by Ceit promotes a new generation of collaborative, safe, and efficient factories, comes to an end

An initiative funded with €3.4 million by the CDTI that integrates advanced robotics, immersive interfaces, and digital twins to optimize processes and improve industrial safety.

16 | 12 | 2025

The project, coordinated by Ceit developed in collaboration with Tecnalia, Ikerlan, CTC, and Aidimme, validates core topic technologies core topic accelerate the transition towards a more flexible, connected, and data Industry 4.0.

The industry is moving towards more flexible, connected production models geared towards data decision-making. This change, driven by technologies such as collaborative and mobile robotics, virtual and augmented reality, and cyber-physical systems, is transforming the way factories are designed, operated, and maintained. In this context, FABRICARE has emerged, a project that seeks to respond to the growing demand for solutions that reduce production times, increase safety, and lower costs through smarter and more efficient processes.

FABRICARE (Collaborative, safe, and intelligent manufacturing through advanced interfaces, robotics, and digital twins) has concluded after intense research development activity development lines of work consider different technologies within intelligent manufacturing in collaborative environments. Funded with €3.4 million by the CDTI through the Cervera Call for Technology Centers of Excellence 2023, the project led by Ceit developed in partnership the technology centers Tecnalia, Ikerlan, CTC, and Aidimme.

Integration of robotics, perception systems, and digital twins

FABRICARE's integrated vision focuses on improving current manufacturing processes through the deployment of collaborative and mobile robotics, reliable perception systems, and their direct connection to a simulation and modeling platform based on digital twins. This platform allows the behavior of the production process to be predicted and analyzed before execution, while facilitating real-time monitoring and control.

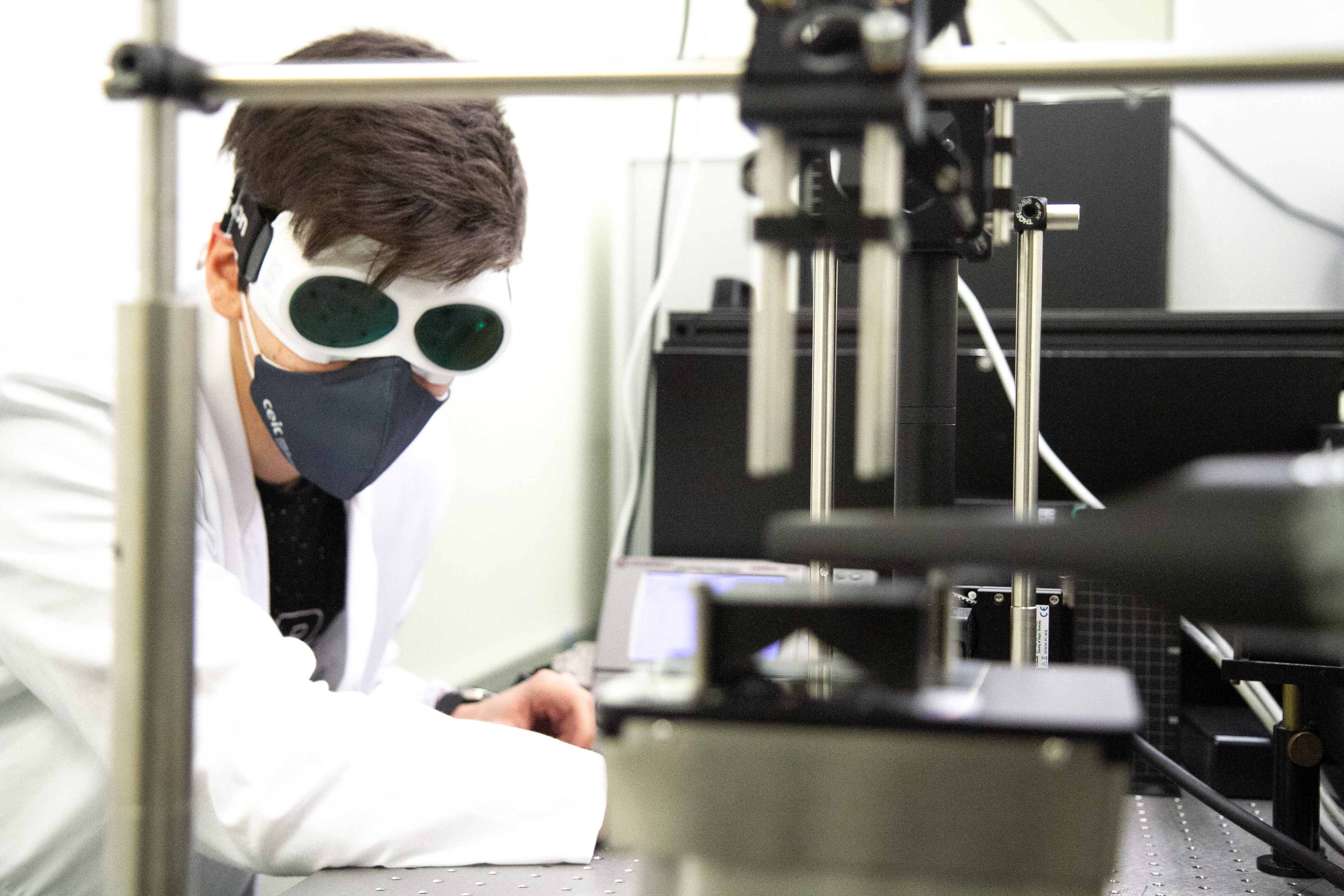

In addition to coordinating the project, Ceit contributed its knowledge expertise to the development digital twins for simulation, new haptic interfaces, advanced controllers for collaborative manipulators, environmental perception sensors, and mobile robot localization by combining optical techniques with radio frequency. As Diego Borro, Ceit researcher Ceit coordinator , points out , "this project Ceit leadership Ceit the development technological solutions for the digital transformation of industry, consolidating a track record of more than two decades of research these technologies."

On November 13, Ceit meeting project was held at the Ceit facilities, a meeting which the results obtained were reviewed and the coordination and work of the consortium was highlighted. "The results have been very positive and reflect the excellent work by the entire team," says Diego Borro. The solutions developed by FABRICARE have demonstrated the potential for designing factories in more flexible, automated, connected, secure, and intelligent environments.

The following video sample demonstrator developed by Ceit combines automated and collaborative disassembly technologies, product inspection, and logistics using mobile robotics.