Ceit trabaja para reducir la dependencia de materias primas críticas mediante la revalorización de virutas metálicas

Ceit to reduce dependence on critical raw materials by revaluing metal shavings.

11 | 11 | 2025

The Basque components industry is heavily dependent on strategic materials such as titanium, nickel, aluminum, and copper alloys, which are essential in high added value sectors added value aeronautics, automotive, rail, biomedical, and valves/oil & gas. The weight of raw materials in production costs, which accounts for around 61%, leaves companies exposed to price fluctuations and supply risks, reducing their room for maneuver and industrial autonomy. In the Basque Country, around 20,000 tons of shavings from these alloys are generated each year, representing an estimated loss of value of 135 million euros, not counting other relevant metals such as magnesium, beryllium, and stainless steels.

Upcycling technologies for circular metal use

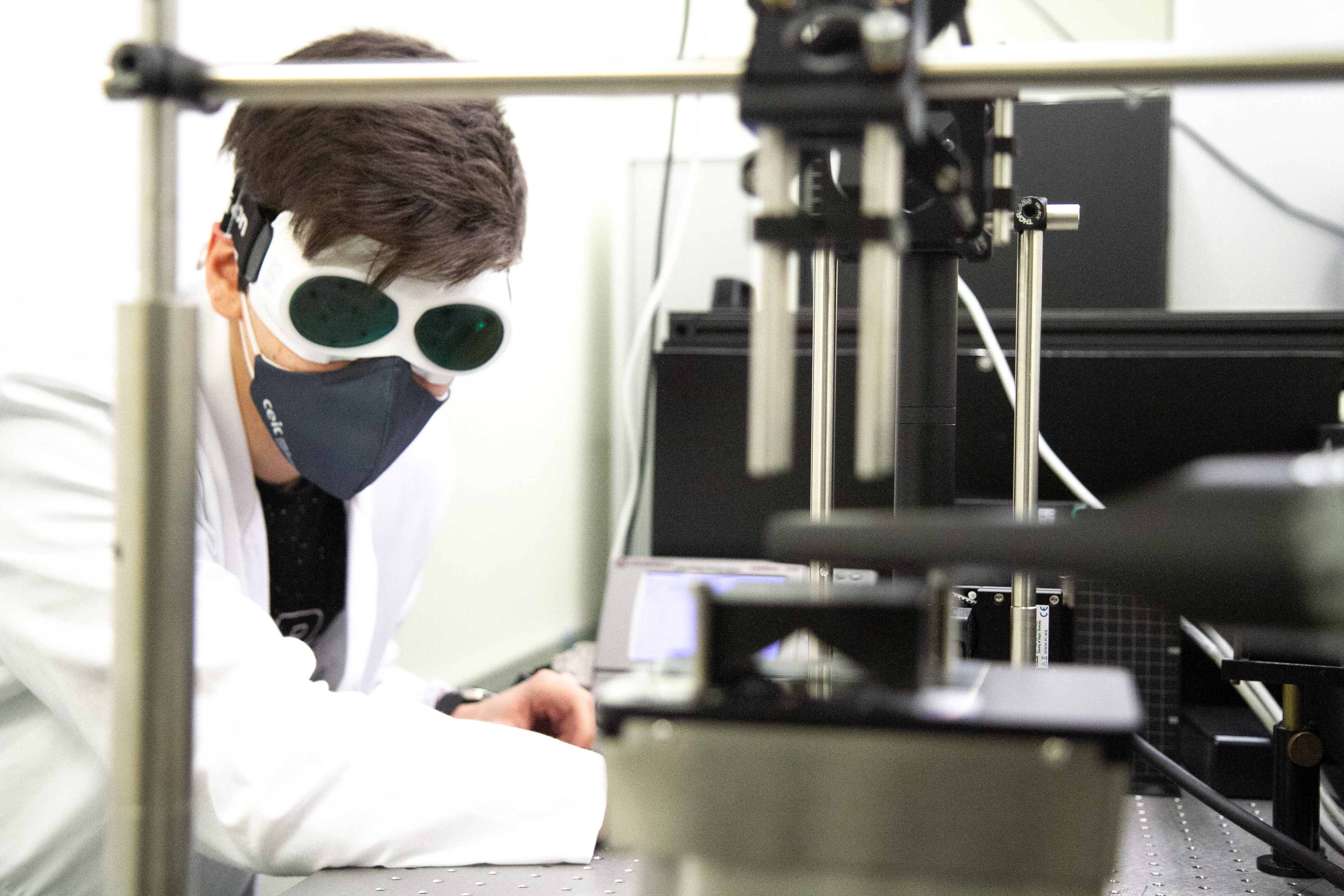

To address this issue, the Ceit technology center Ceit joined the project . Starting with the chips generated during machining, the project innovative, low-energy recovery technologies capable of restoring the material's original chemical and mechanical properties. This will allow the chips to be reincorporated into near-net-shape (NNS) processes, such as forming or additive manufacturing, offering a more sustainable and efficient alternative to traditional melting recycling methods.

Ceit the development new techniques for manufacturing powder from shavings using decrepitation processes, and will work on the direct revaluation of titanium alloys in a solid state by applying advanced technologies such as hot isostatic pressing (HIP) and high-pressure torsion (HPT). These techniques will enable the production of consolidated material for different uses, creating an work window of work for recycled powders applicable to additive manufacturing and NNS processes.

A more sustainable and autonomous European value chain

REVIR, funded by the Basque Government's Elkartek program through SPRI, involves the participation of Mondragon University, the University of Deusto, Azterlan, Lortek, Tecnalia, the University of the Basque Country, Tekniker, and Ceit. The project lay the instructions a European value chain for the recycling of critical material chips, connecting manufacturers, recyclers, and technology centers. This will promote a more sustainable, competitive, and autonomous industry in the Basque Autonomous Community, with a lower carbon footprint and less dependence on strategic imports.